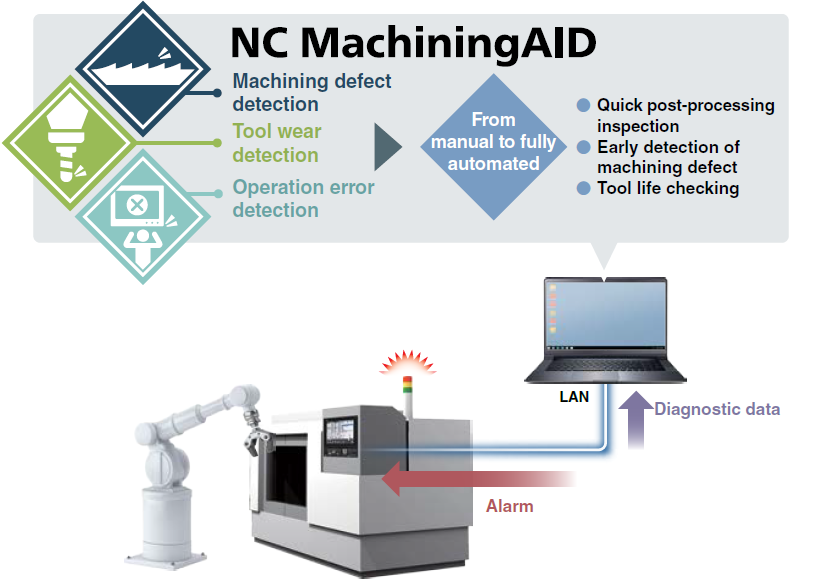

IoT-related Products NC MachiningAID

Overview

Today, we have seen various problems on CNC shop floors. Skilled workers are very few, part variety is getting wider, capital cost for automation is increasing, and material and tools are getting expensive, which are all unavoidable causes that push up the cost. Even after you decide to start using DX, you may often face technical problems such as difficulty in understanding how the data should be used. NC MachiningAID retrieves and analyzes the Mitsubishi Electric's CNC machining data and automatically performs diagnostics to realize full automation and reduce your machining costs as well.

You can reduce

- ●Waste & scrap

- ●Tooling cost

- ●CO2

Features & Use Case

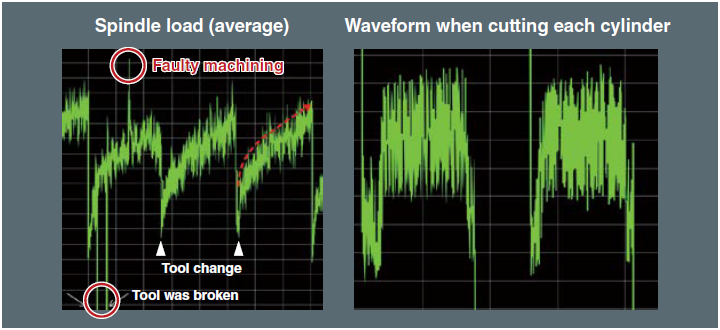

Machining defect detection

Eliminates unsatisfactory machining

with accurate diagnostic technologies!

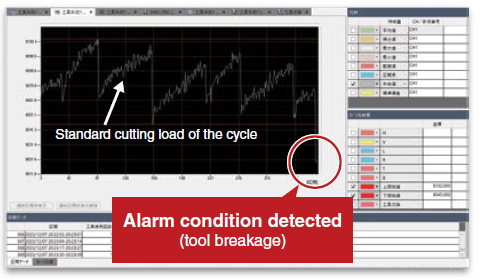

Machine shops are required to be able to handle fluctuating production demands. NC MachiningAID automatically learns the good machining condition and generates an alarm when it detects bad machining. This works like a manual quick inspection traditionally done by a human. In combination with a robot, the manual operation can be completely automated.

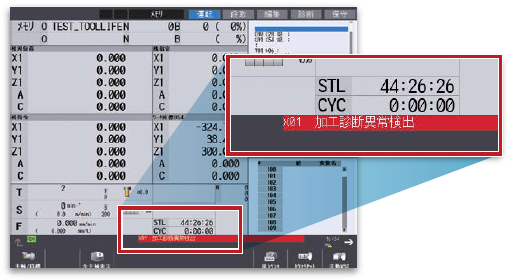

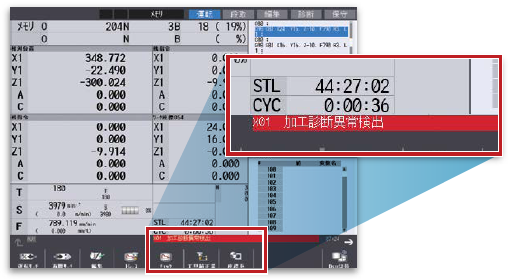

■ Alarm indication during machining (with cycle stop)

Falling below a threshold means the tool is broken

Use Case Car engines

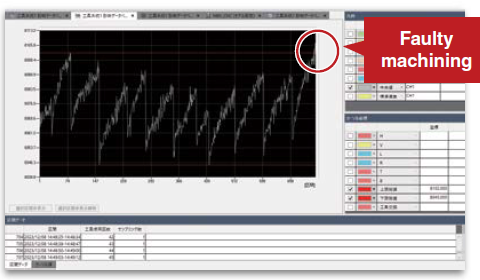

Abnormal machining diagnosis of bore boring

- Machine tool

- Machining center

- Workpiece/machining

- MaterialCast iron (Bore sleeve)

CNC machiningBore boring - Result

- Faulty machining condition confirmed from the average spindle load during Bore boring

■ Machined part (for illustration purpose)

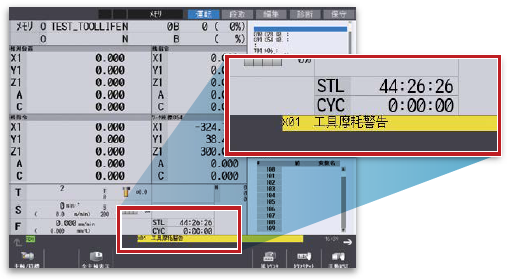

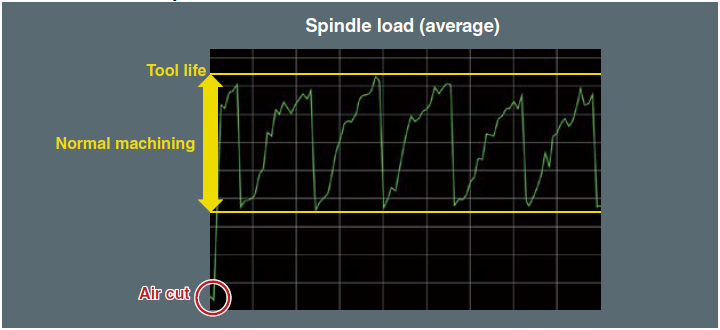

Tool wear detection

Automatically learns tool life.

Suggests tool change with perfect timing to reduce your tooling costs!

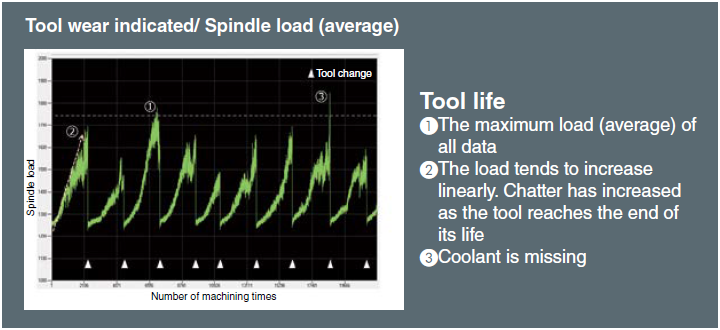

NC MachiningAID automatically identifies the feature associated with tool wear from the features of each axis and the correlation between the tool usage, then automatically learns the tool life on a process-by-process basis. Once trained, the NC MachiningAID predicts the tool deterioration (erosive wear) on a machining-by-machining basis, and when the tool is nearing the end of its life, it indicates a corresponding CNC alarm message to organize the user to change the tool.

■ The control does not stop the operation when alarmed, warned or alerted due to a tool wear.

Use Case Machining an artificial joint

Turning tool wear diagnostics

- Machine tool

- Lathe machine

- Workpiece/machining

- MaterialCobalt-chromium alloy

CNC machiningTurning - Result

- Monitors tool wear during precision machining to achieve solid surface quality.

■ Machined part (for illustration purpose)

Operation error detection Eliminates Human Error and Reduce the Risk of Scrap!

Variation of production and High-mix Low-volume manufacturing are often the cause of human error. How we can minimize the risk of human error is our important topic. NC MachiningAID automatically learns the conforming cut and detects errors, such as inadequate coolant discharge rate, improper workpiece chucking, and incorrect tool compensation settings. This is also applicable to machining errors caused by incorrect robot maneuvers.

■ Alarms related to human errors

Compares to upper threshold to detect human error

Use Case Tapping (screw) operation for electric part

Tapping Diagnosis of faulty machining

- Machine tool

- Machining center

- Workpiece/machining

- MaterialFCD

CNC machiningTapping - Result

- It is confirmed that tool wear during tapping and chatter of the worn tool can be used to detect human error.

■ Machined part (for illustration purpose)