MELSEC MX Controller MX-F model

Product features -Concept-

Concept

The MELSEC MX Controller integrates three types of control, sequence, motion, and network.

The MELSEC MX Controller has two models: MX-R model and MX-F model.

A diversified and sophisticated system can be constructed by using the MX-F models with the MELSEC iQ-F Series modules.

One controller for all your control needs

Decades of expertise in programmable controller technology have been combined into a single controller.

By integrating sequence control, motion control, and network control on the MELSEC MX Controller platform, faster and more accurate control is achieved.

We will continue to add functionality to this platform, making it adaptable to a wide range of applications.

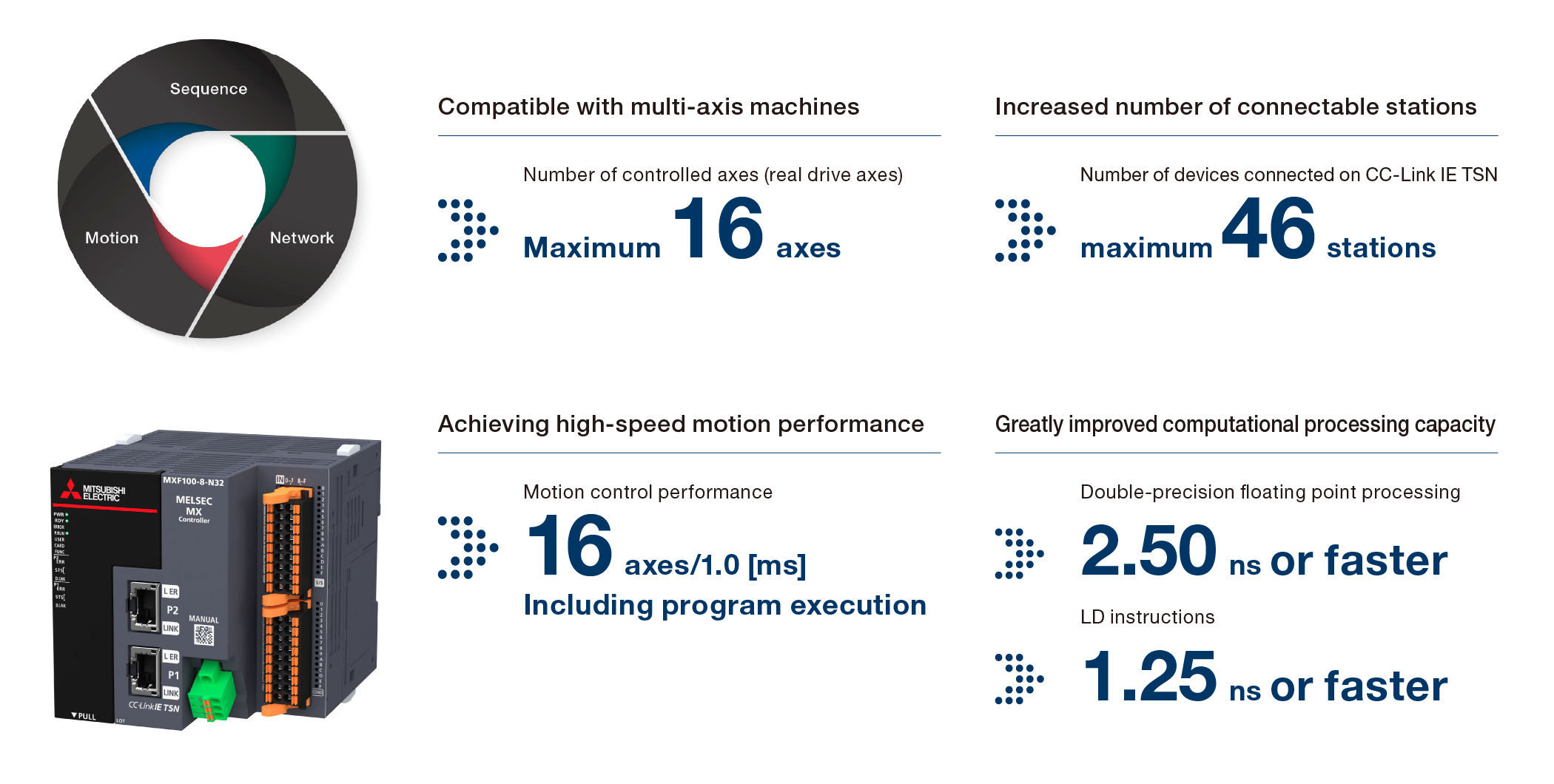

Equipped with a high-performance multi-core MPU as standard, enabling high-speed control

All functions of sequence, motion, and network are integrated, achieving high-speed and high-accuracy motion control.

All-in-One Various Functions

Compact Design, Infinite Functions

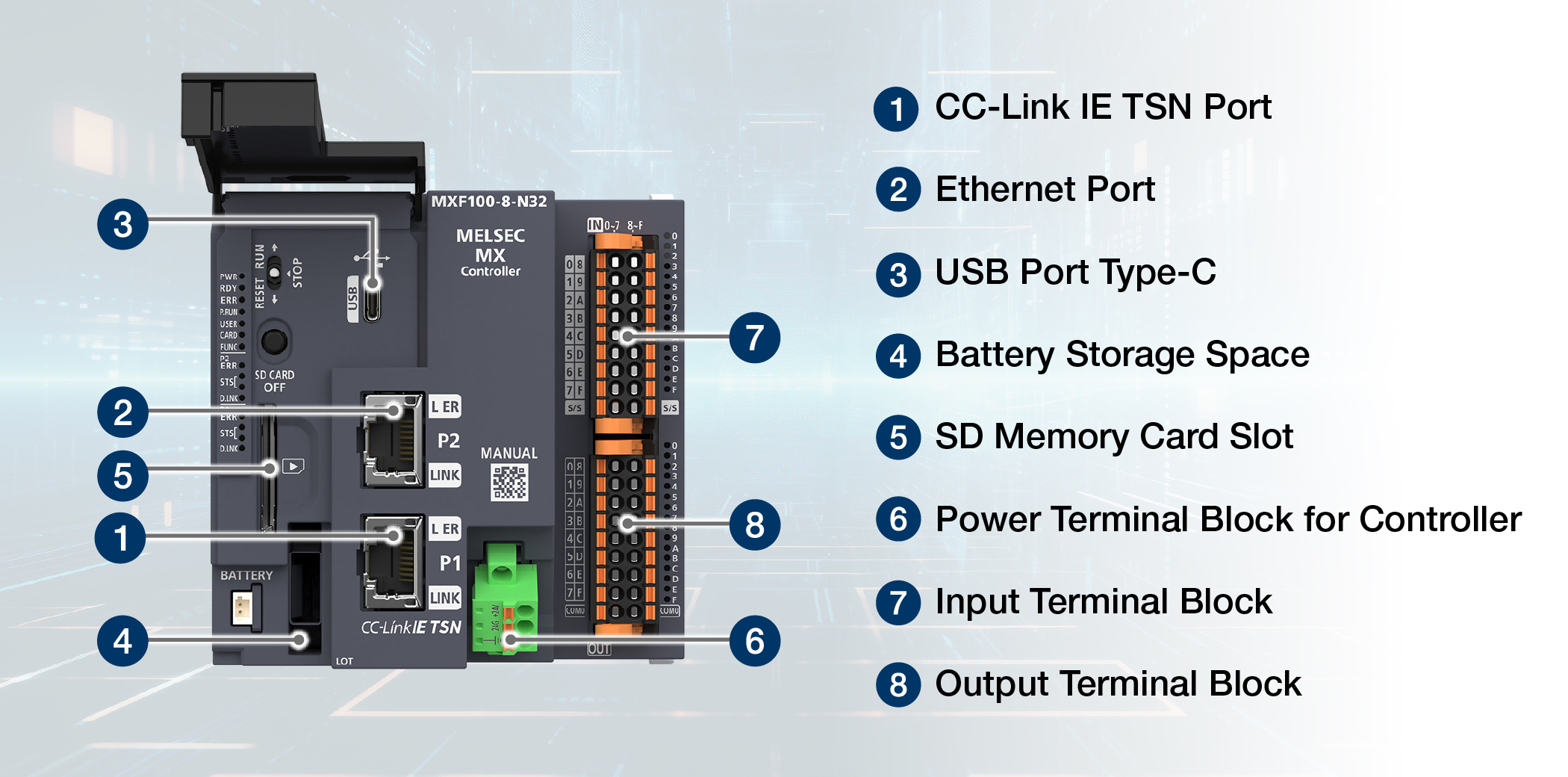

- Standalone Type That Can Be Installed in Various Scenes

- Equipped with Ethernet port compatible with high-speed, large-capacity CC-Link IE TSN. Achieve large-scale IoT with a compact body.

- With a multi-core MPU, achieving high-speed, high-precision motion control and detailed sequence control simultaneously.

- Built-in 32 points of I/O, 4-axis pulse positioning, and 8-channel high-speed counters.

Maximizing the performance of small to medium-sized systems

Upgrading small to medium devices to advanced systems.

- Optimizing controller load under various mechanisms through mixed operation cycles. Maximizing control specs by utilizing mechanical structures.

- Advanced synchronous control functions replace hardware like gears, shafts, transmissions, and cams with software, simplifying mechanical structures to the utmost.

- CC-Link IE TSN embodies high-speed, high-precision, low-jitter performance to optimize drive and sensor, minimizing waste and maximizing product yield.

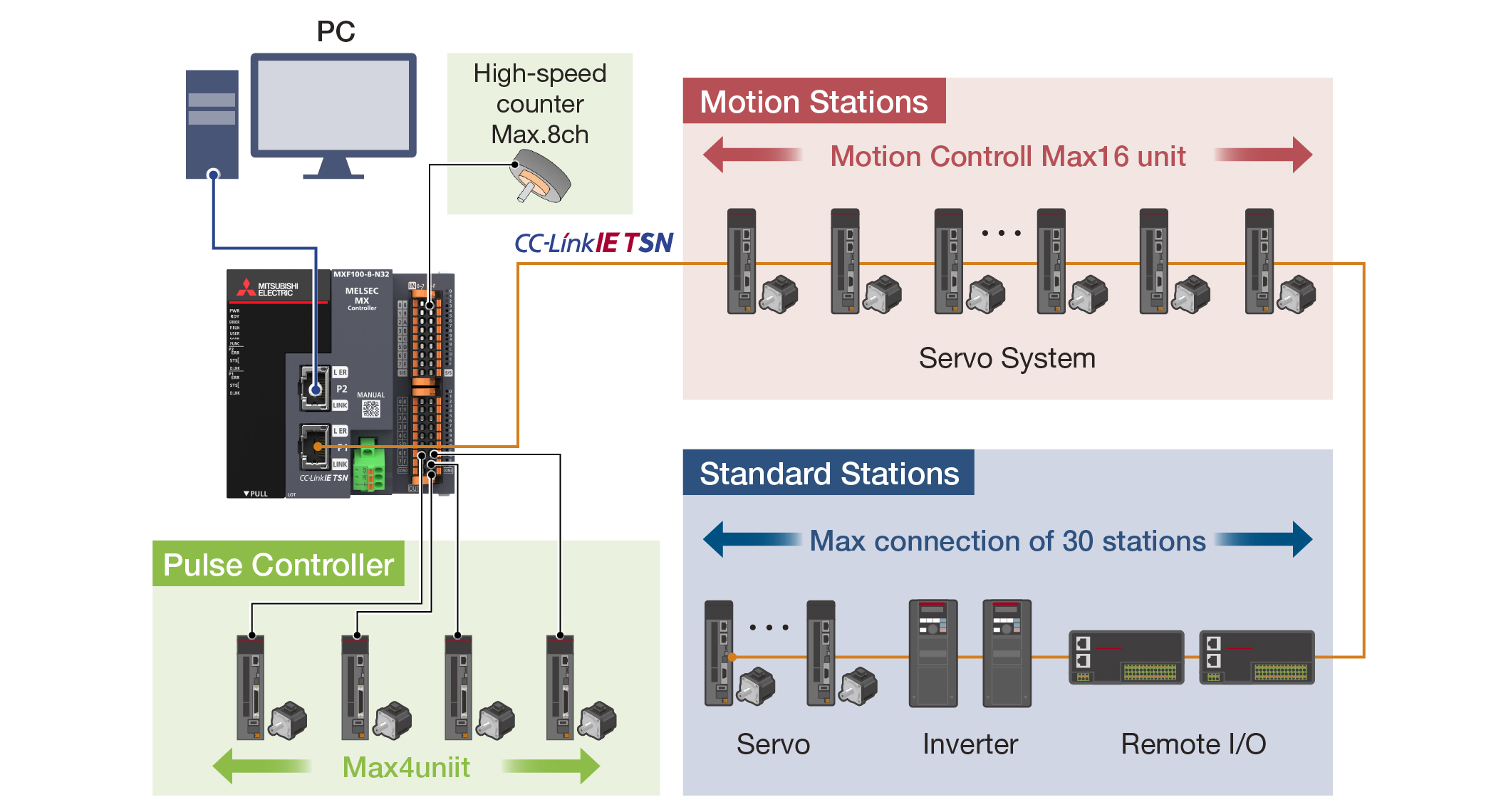

One device enables diverse control options

Connected in many ways

- Built-in CC-Link IE TSN enables control of up to 16 motion stations with synchronization as fast as 250μs.

- One Ethernet cable connects up to 30 standard stations and 16 motion stations, reducing wiring and labor while allowing control of main and peripheral devices with a single unit.

- The built-in I/O supports 4-axis pulse positioning and 8-channel high-speed counters, using existing pulse control mechanisms to lower equipment costs.

*1:Future support

*2:The number of virtual axes is not included in the number of controllable axes.

Easily expandable and extendable

Simple installation, that's the best

- With a base-less, standalone design and built-in features, the controller can be used to construct a system on its own.

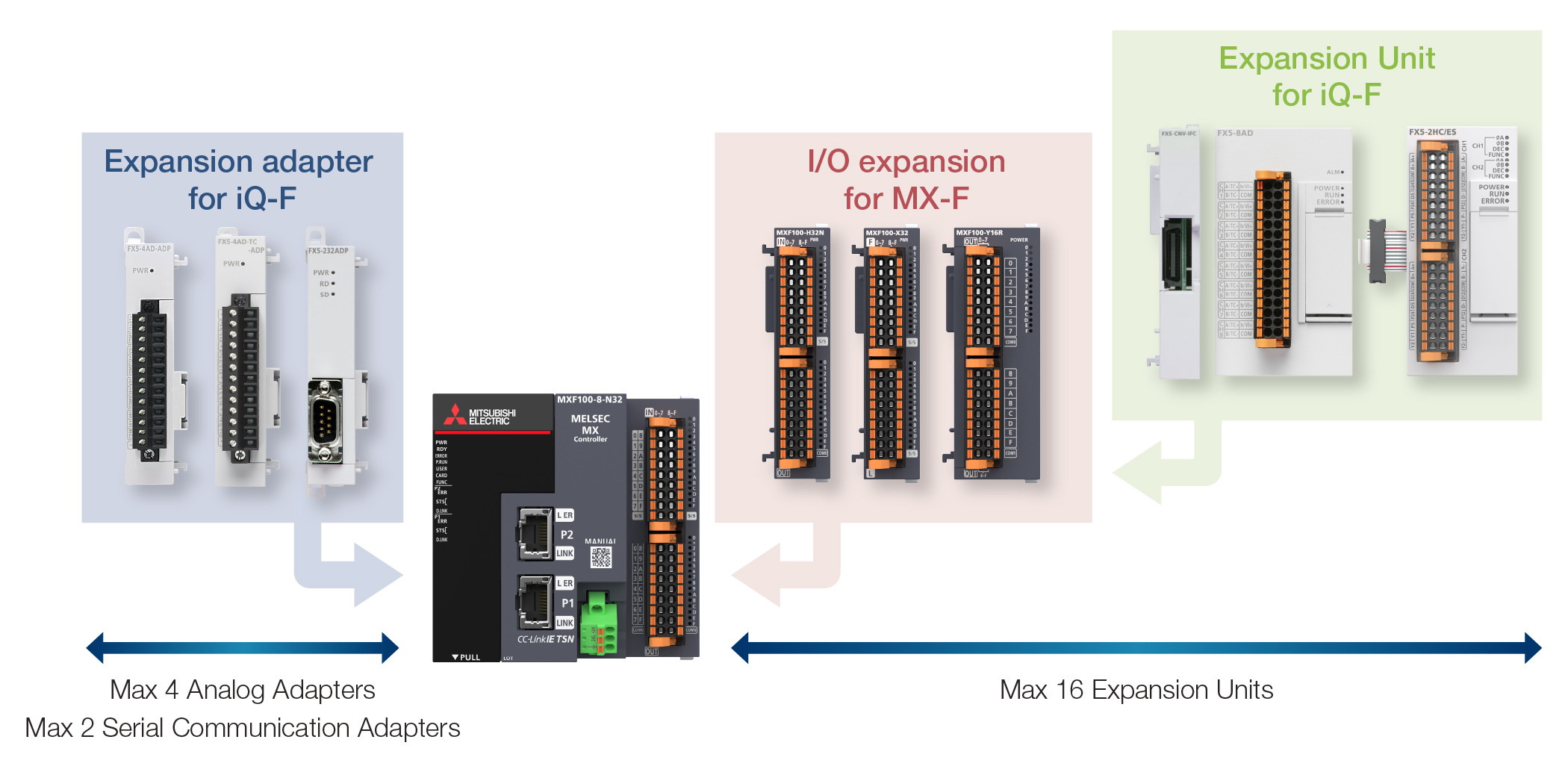

- An I/O module with a maximum of 512 points can be added, and expansion adapters and extension modules for the MELSEC iQ-F series can be used.

- Various functions and performance, such as AD/DA conversion and temperature control, can be achieved at any installation location.

Product features

Achieve multi-axis machine control with one controller

The MX Controller, equipped with a high-performance multi-core MPU as standard, integrates sequence, motion, and network control, supporting up to 256 axes. It supports mixed operation cycles, ensuring high-speed control even with multiple axes. One controller delivers precise control of individual mechanisms and control of the entire production line.

Reduce programming time and streamline development with one-tool engineering and intuitive operation

Sequence control and motion control programs are combined into one. There is no need to create separate programs for each module or exchange data, simplifying your programs. With a single tool handling both sequence and motion control programs, you can easily modularize the program into components, manage change history, and debug.

Significantly reduce downtime with visibility into issues

Achieve speedy root cause analysis through system-wide recording of operational status and extraction of anomalies using AI.

Achieve centralized management and sharing of valuable data

Boost work efficiency through data sharing and centralized management.

Information can be shared from each device to the IT system.