MELSEC MX Controller MX-F model

Products -Reducing the machine management cost-

- Significantly reduce downtime with visibility into issues

- Record system-wide data over the network

- Root cause analysis made easy with coordination between tools

- Speed up program debugging and analysis

- AI-assisted root cause analysis

- Automatically generate network parameters

- Reduce maintenance time with automatic parameter distribution

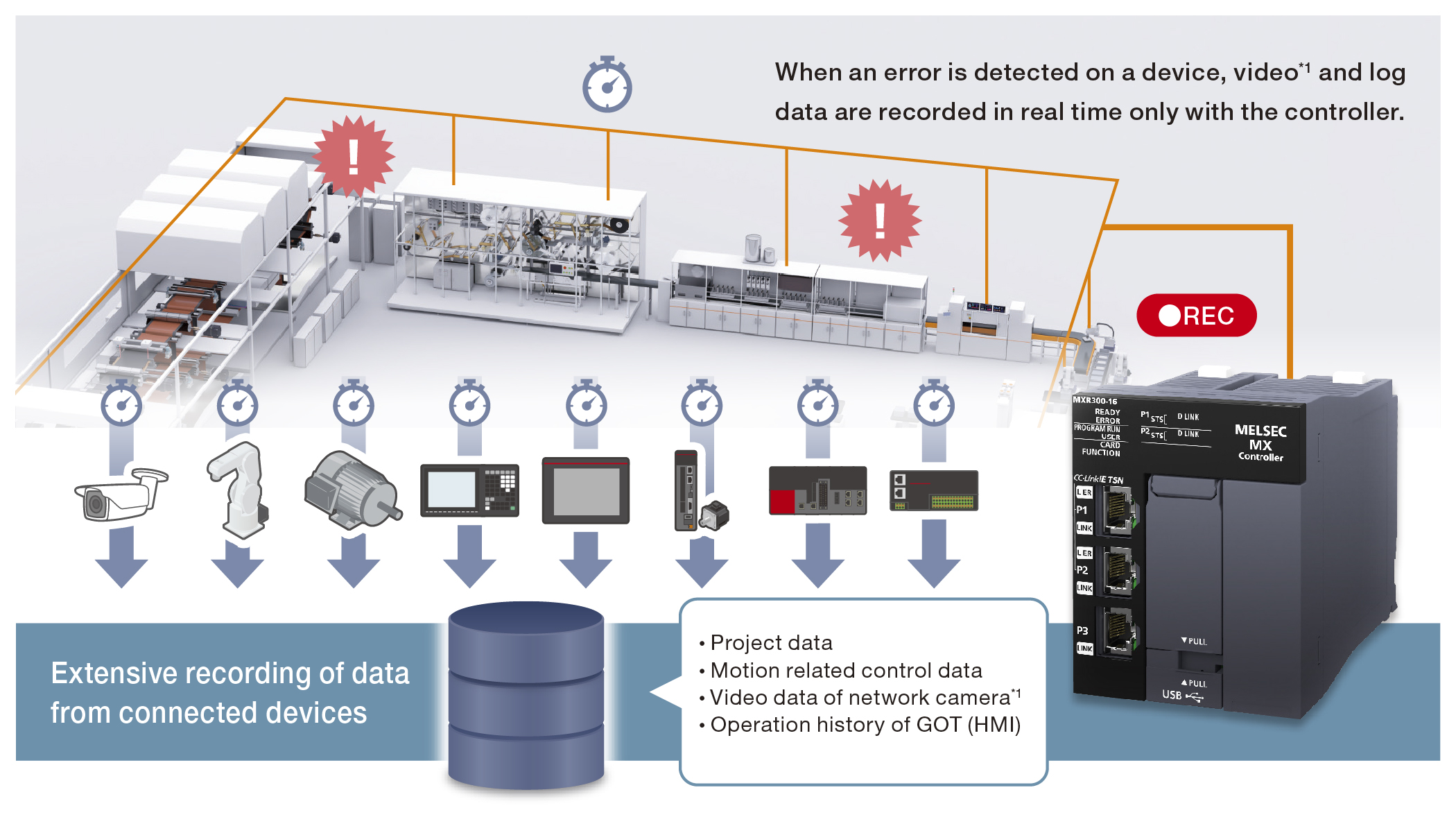

Significantly reduce downtime with visibility into issues

Achieve speedy root cause analysis through system-wide recording of operational status and extraction of anomalies using AI.

Record system-wide data over the networkFuture support

Workpiece status and operation history are fully recorded along with control data from each equipment and machine before and

after a problem occurs. View time-synchronized recorded waveform data, programs and video to easily identify the root cause.

This allows you to quickly and comprehensively investigate the cause and prevent problems from recurring.

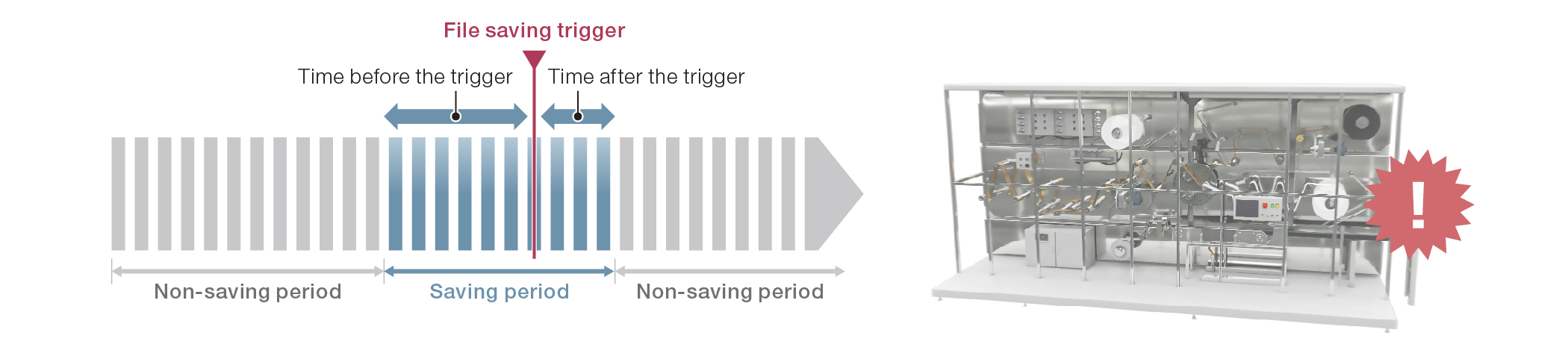

Data is automatically recorded before and after a problem occurs and at the start of the facility cycle

Recording before and after a problem occurs

- ■Data is recorded for specified periods before and after a problem occurs, enabling efficient root cause analysis

*1: A camera recorder module is required.

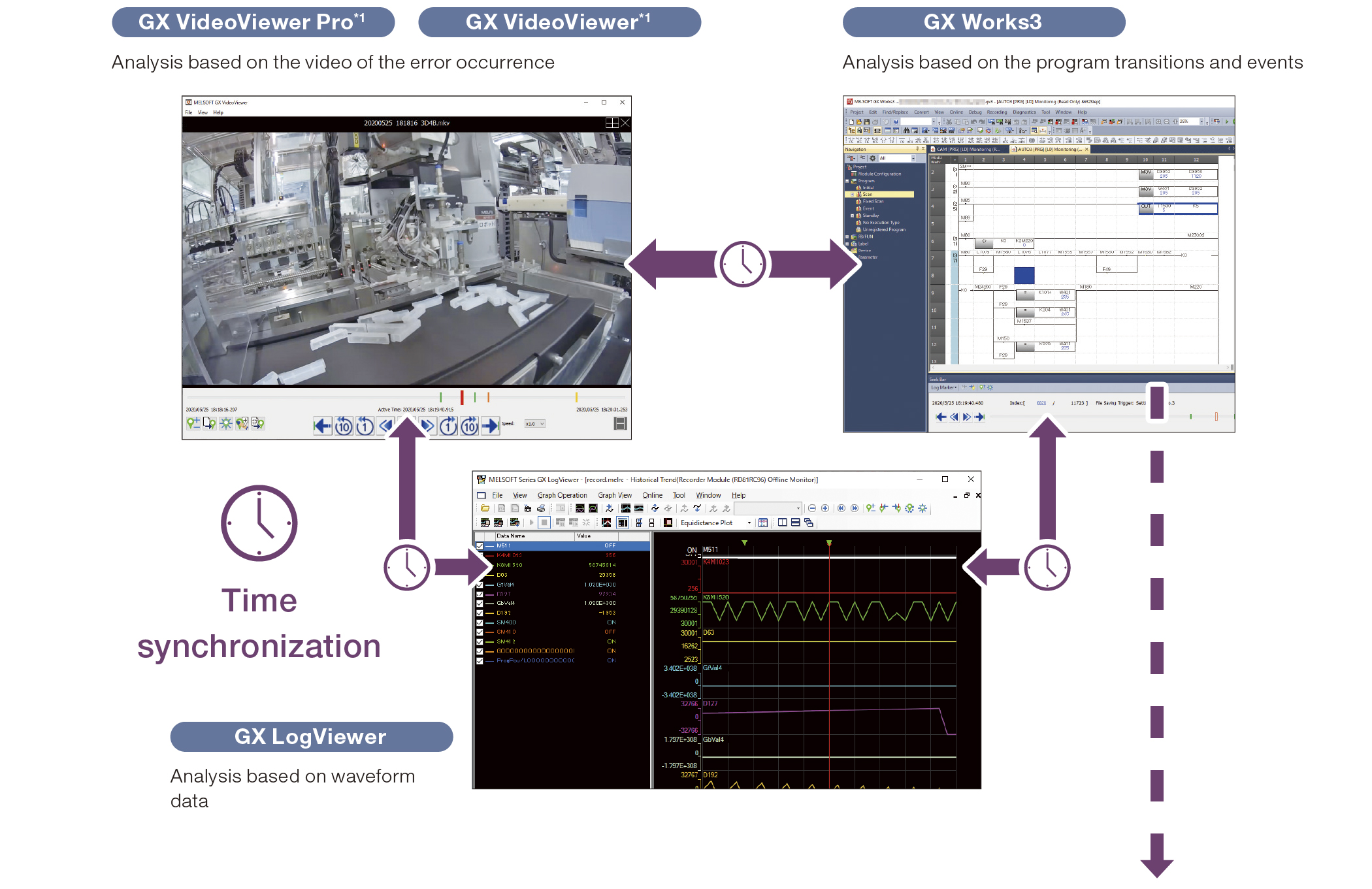

Root cause analysis made easy with coordination between toolsFuture support

Even if the playback speed is changed, the timing between the video, program monitor, and device waveform data can be

maintained, each showing the target moment.

You can analyze from multiple perspectives while checking points of change.

Check the range affected by a device/label at a glance

You can check the range affected by a device/label at a glance, making it easy to perform integrated analysis.

*1: The MX-F model is not supported.

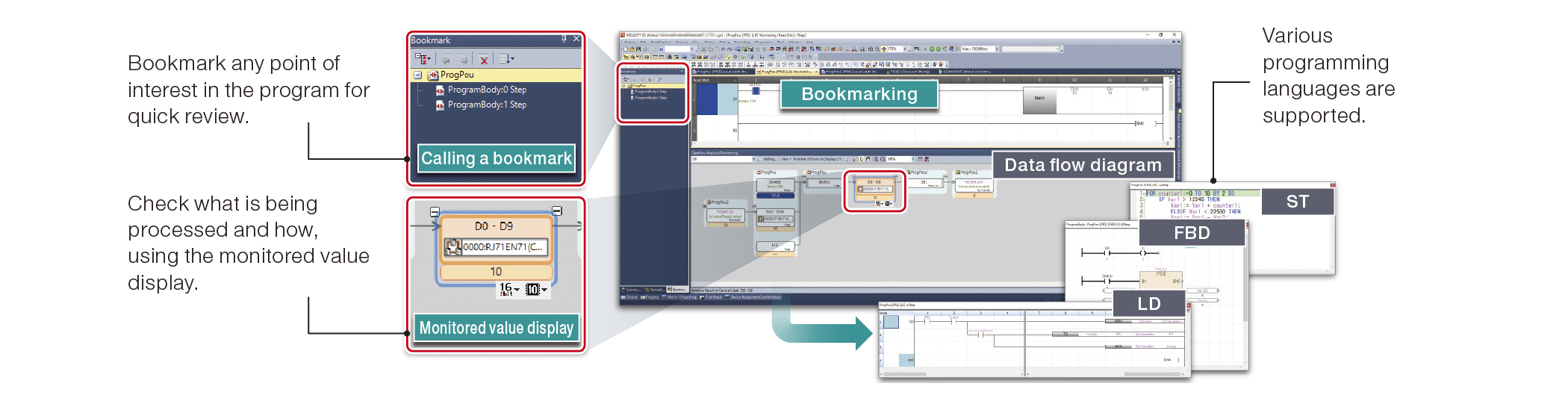

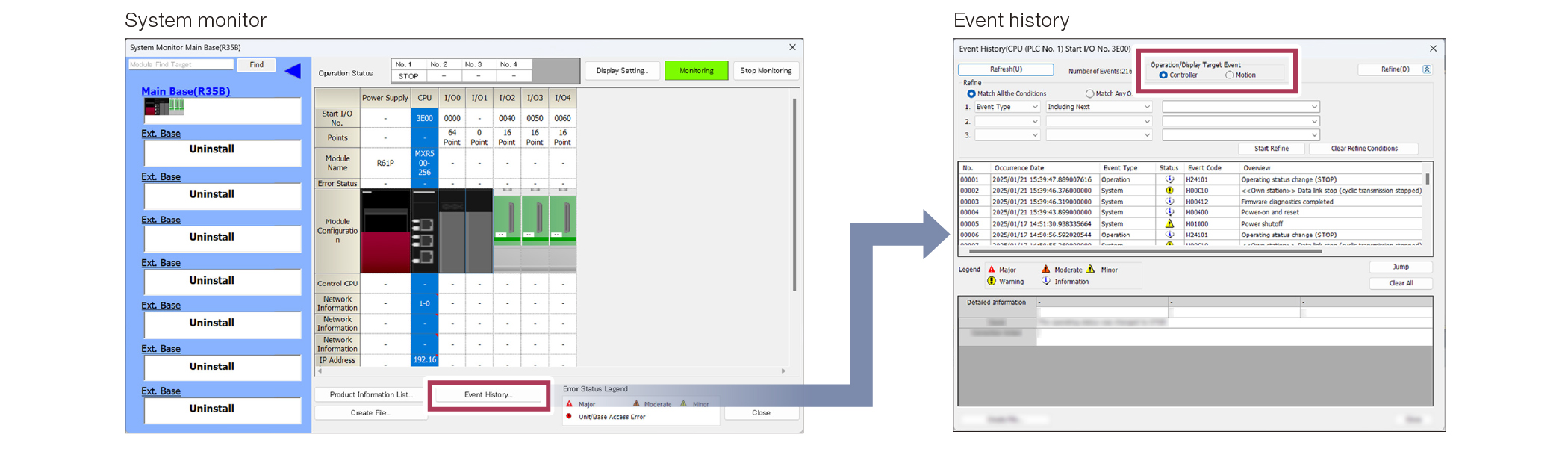

Speed up program debugging and analysis

Easily identify problematic code using GX Works3 diagnostic function. Use the system monitor to check the module configuration and the error status of the system. View the event history to see errors and operations performed in the controller and motion in chronological order, including detailed error information, causes, and corrective actions.

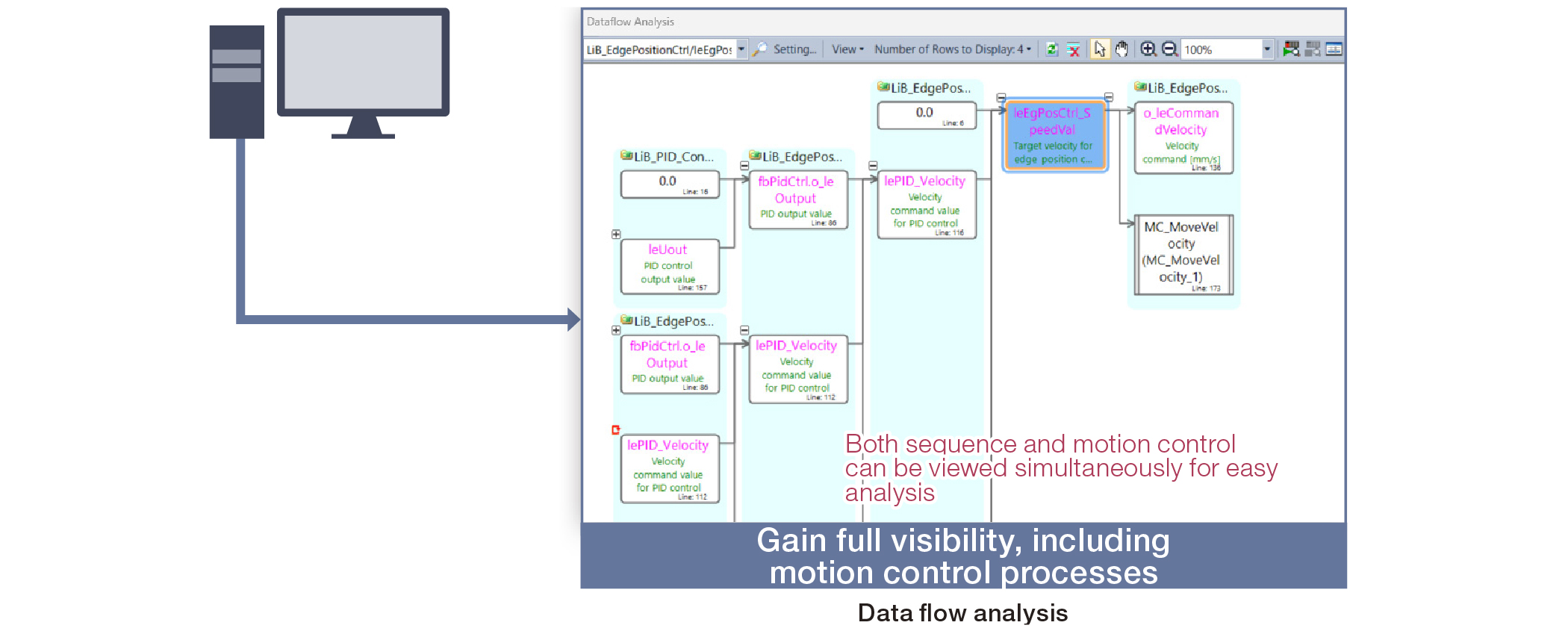

Analyze both sequence and motion programs simultaneously

One-stop search and analysis are available even for large programs with many labels and structures.

Select data of interest (device or label) to visually display related data that affects changes in the selected data in a flow diagram.

You can jump from the flow diagram to the corresponding part of the program, making it easy to identify the cause.

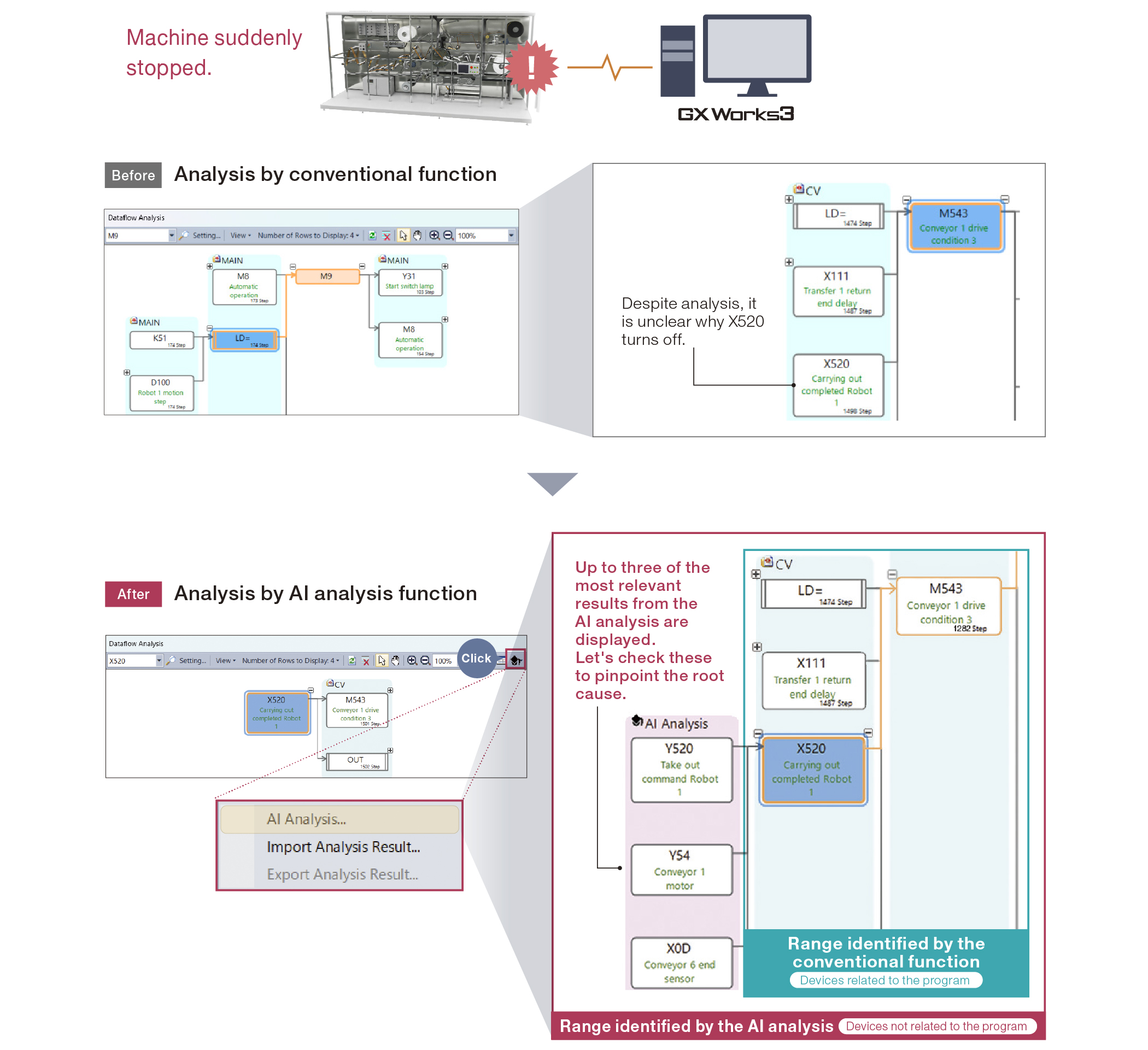

AI-assisted root cause analysisFuture support

Track device relationships that are not apparent in the program using AI. Efficiently debug issues where the program appears fine but the equipment stops without generating errors through AI-powered data flow analysis. For AI analysis, recording and logging files from normal operation of the equipment or machine are required.

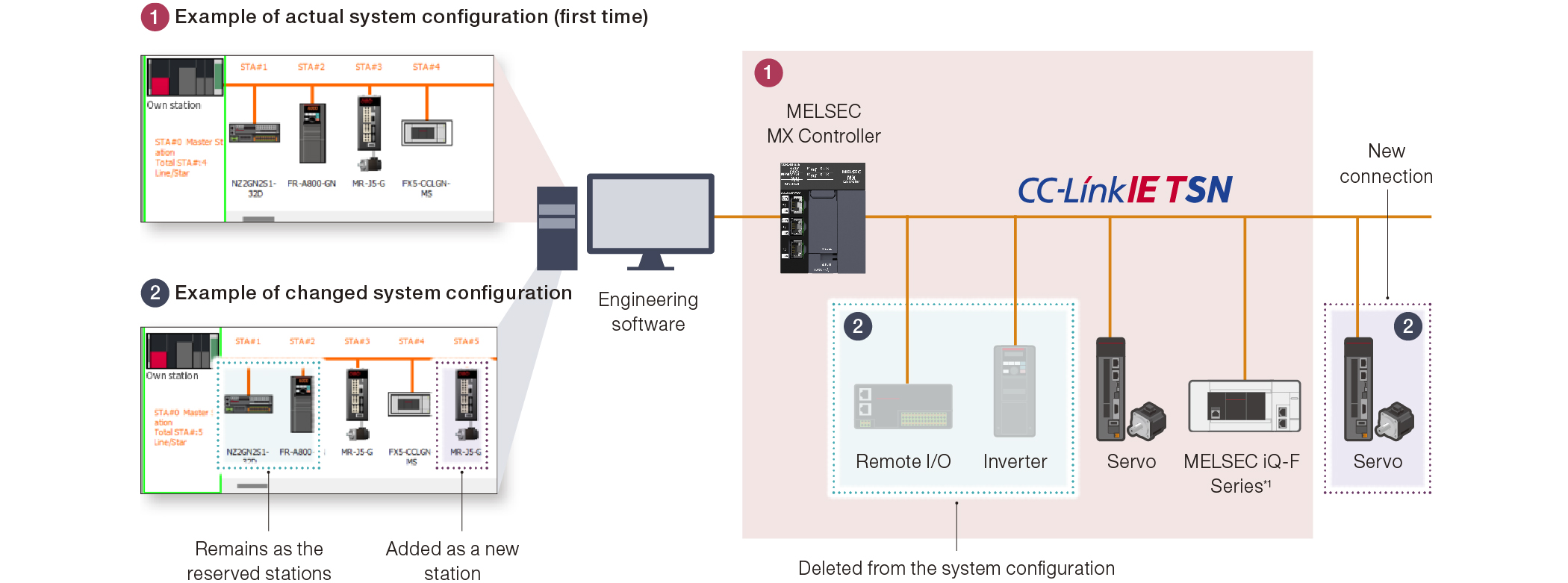

Automatically generate network parametersFuture support

Simply connect the engineering software to the master station and click a button on the screen to automatically detect the system configuration and generate network parameters. Even if the system configuration is changed, you can easily update the parameters with the same simple operation. This significantly reduces network setup time.

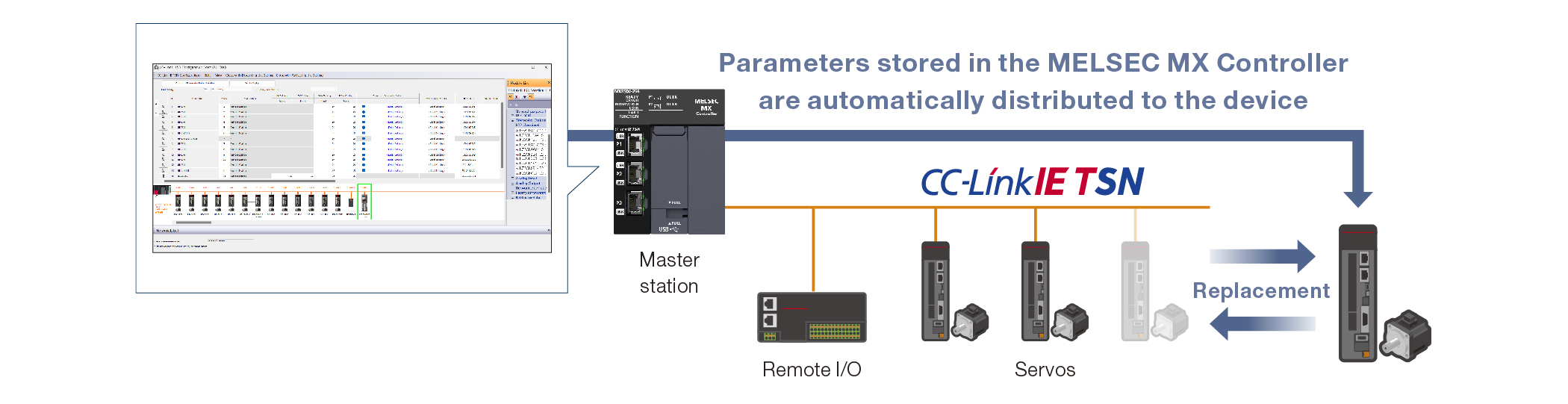

Reduce maintenance time with automatic parameter distribution

When a device is powered on or reconnected, parameters stored in the master station are automatically distributed to the device.

Even after replacing a device, there is no need for individual parameter writing, ensuring a smooth and efficient replacement

process.

*1: Local stations will be supported in the future.