MELSEC MX Controller MX-R model

Product features -Concept-

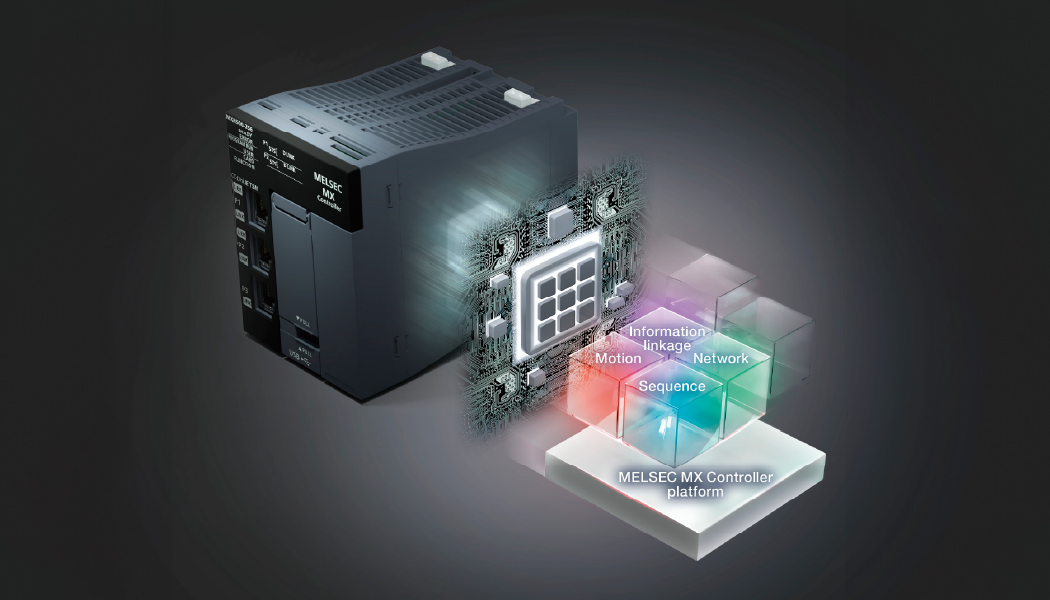

Concept

The MELSEC MX Controller is a series of controllers that integrates three types of control, sequence, motion, and network.

The MELSEC MX Controller has two models: MX-R model and MX-F model.

A diversified and sophisticated system can be constructed by using the MX-R models with the MELSEC iQ-R Series modules.

One controller for all your control needs

Decades of expertise in programmable controller technology have been combined into a single controller.

By integrating sequence control, motion control, and network control on the MELSEC MX Controller platform, faster and more accurate control is achieved.

We will continue to add functionality to this platform, making it adaptable to a wide range of applications.

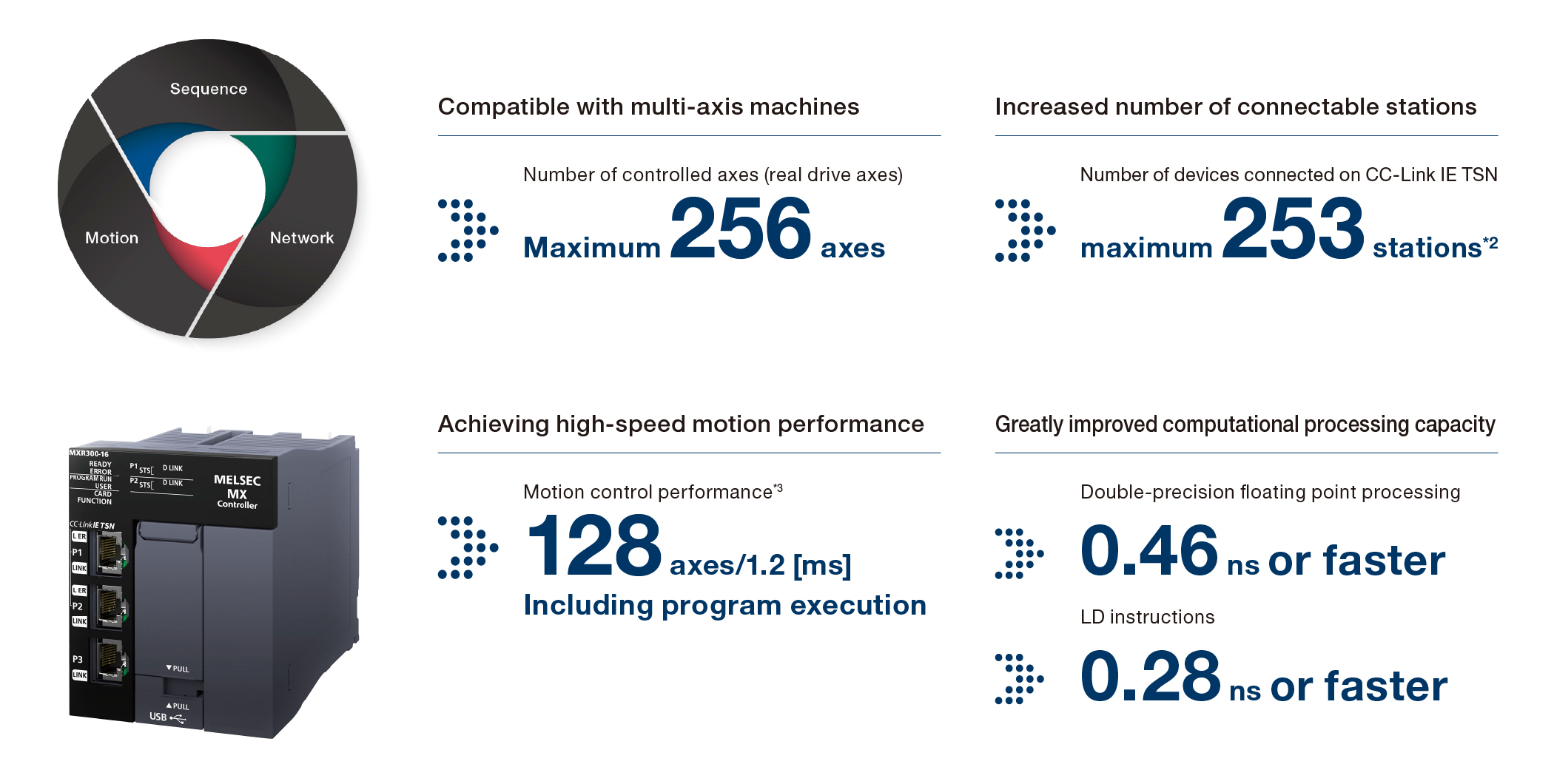

Equipped with a high-performance multi-core MPU as standard, enabling high-speed control

All functions of sequence, motion, and network are integrated. The motion control performance is about 10 times*1 higher than existing products of Mitsubishi Electric, achieving high-speed and highaccuracy motion control.

- *1:Comparison with the MELSEC iQ-R Series (64-axis control)

- *2:Device stations supporting connections to 253 stations will be available in the future. For details, refer to the Technical Bulletin (FA-A-0451).

- *3:When the motion operation cycle setting is 1.5 ms

Product features

Achieve multi-axis machine control with one controller

The MX Controller, equipped with a high-performance multi-core MPU as standard, integrates sequence, motion, and network control, supporting up to 256 axes. It supports mixed operation cycles, ensuring high-speed control even with multiple axes. One controller delivers precise control of individual mechanisms and control of the entire production line.

Reduce programming time and streamline development with one-tool engineering and intuitive operation

Sequence control and motion control programs are combined into one. There is no need to create separate programs for each module or exchange data, simplifying your programs. With a single tool handling both sequence and motion control programs, you can easily modularize the program into components, manage change history, and debug.

Significantly reduce downtime with visibility into issues

Achieve speedy root cause analysis through system-wide recording of operational status and extraction of anomalies using AI.

Achieve centralized management and sharing of valuable data

Boost work efficiency through data sharing and centralized management.

Information can be shared from each device to the IT system.