SmartFactory

×

Sustainable

We would like to introduce a lithium-ion battery manufacturing process using the latest factory automation and software products.

Take a look at how the products are made in a sustainable way.

Exhibitions

We exhibited at the "2023 International Robot Exhibition" held at Tokyo Big Sight from Wednesday, November 29, 2023 to Saturday, December 2, 2023.

We exhibited a number of the latest solutions and products under the theme of "Flexible & Sustainable - Robotics supporting your manufacturing lifecycle."

On the special page after the exhibition, you can view the rich content displayed at the real exhibition.

We would like to introduce the products and solutions exhibited at the exhibition.

We would like to introduce a lithium-ion battery manufacturing process using the latest factory automation and software products.

Take a look at how the products are made in a sustainable way.

We would like to explain about our sustainability challenges in the Mitsubishi Electric FA Systems business from the standpoint of contributing to our customers through products and what measures we take during manufacturing.

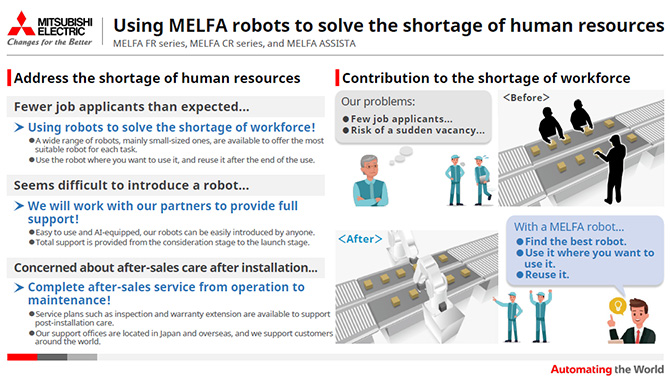

In places with a limited workforce!

Using MELFA robots enables flexible response to changes in the business environment, improves productivity, reduces TCO, and helps solve the problem of labor shortage.

Contributes to reduction of design and start-up man-hours!

Verification of the actual line with MELSOFT Gemini enables reduction of design man-hours, improvement of productivity, and maintenance man-hours!

Improving Labor Productivity through Support for Visualization and Enhancement!

We promote visualization of various work sites through a wide range of achievements and high reliability, not only in factories but also in buildings and social infrastructure.

Contribution to addressing labor shortages through the utilization of AI for quality prediction and predictive maintenance.

Software that digitally replaces human intuition and expertise with AI. It enables data utilization from data analysis to diagnostics without requiring specialized knowledge.

Creating new values with the combined power of companies both inside and outside the group!

We will aggregate data in the digital space to solve the social issues of our customers with integrated solutions that create new values with the combined power of companies both inside and outside the group.

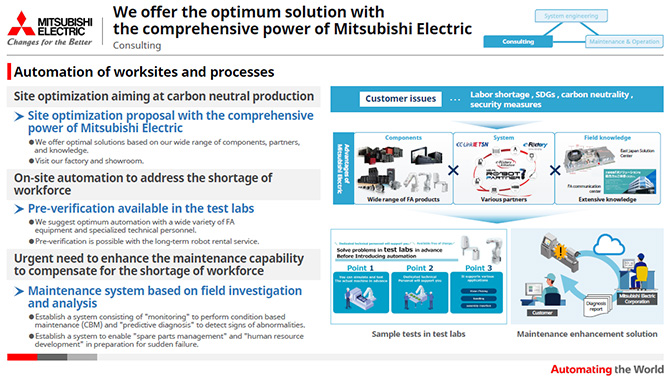

We offer the optimum solution!

By providing the pre-verification support in the test labs or with the robot rental service, we provide optimal solutions with the power of both inside and outside the group.

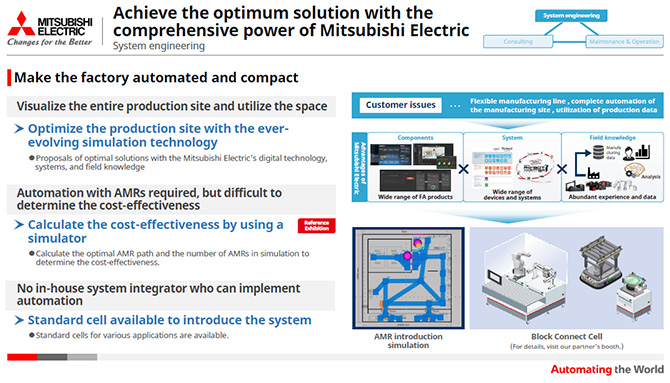

Achieve the optimum solution!

We help customers achieve ideal operation by simulations with various devices such as AMR and sales of cells according to the application.

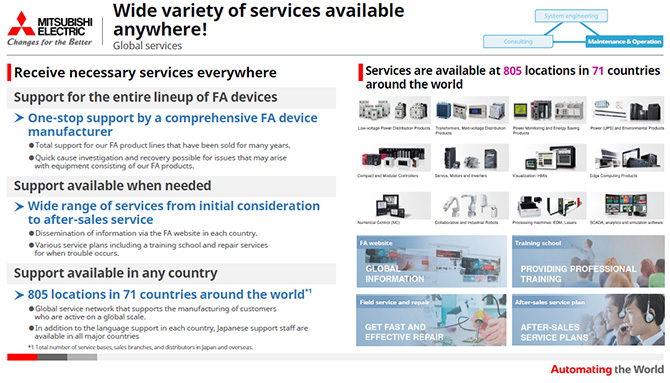

Wide variety of services anywhere!

We support the needs of our customers' production facilities by providing a wide range of services from our service locations around the world.

Keeping robots operating stably

Our robots are optimally maintained using predictive maintenance software and digital inspection with the warranty service provided in the event of a failure, which contributes to the continuous and stable robot operation.

One stop for the best solution

Utilizing our abundant know-how at manufacturing sites, we propose one-stop optimal measures according to the customer's system and situation.

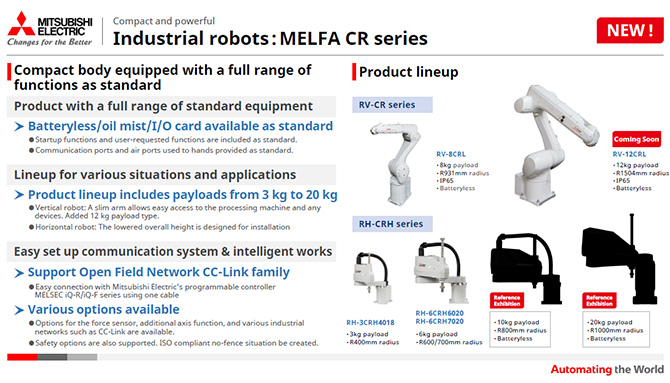

Compact and powerful

The MELFA CR series includes 3 kg to 20 kg horizontal articulated robots and has a growing number of vertical articulated robot models.

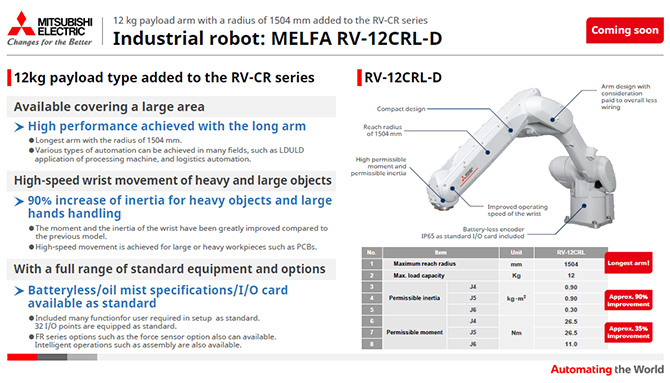

12 kg payload arm with a radius of 1504 mm added to the RV-CR series

The 12kg payload type has been added to the RV-CR series.

Automation is enlarged with features such as a longest arm in the class, wrist reinforcement, and enhanced standard equipment.

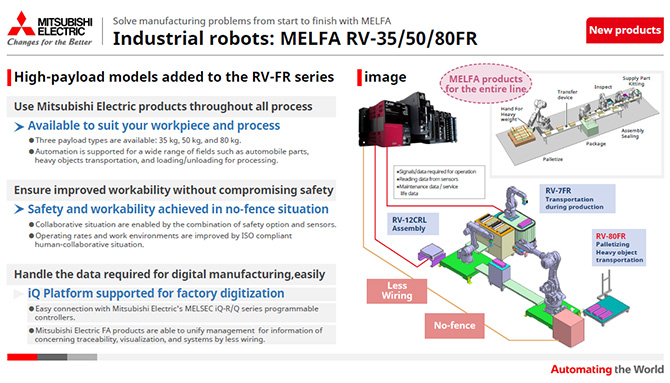

Solve manufacturing problems from start to finish with MELFA

The addition of our new high-payload models allows for production lines run entirely by MELFA series robots. Automation of the transportation of heavy objects and palletizing is enabled.

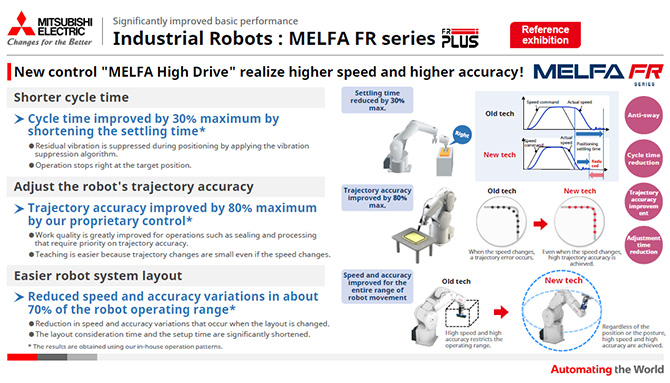

Significantly improved basic performance

We would like to introduce next-generation MELFA FR series robots with high-end features that pursue higher speed positioning and higher trajectory accuracy.

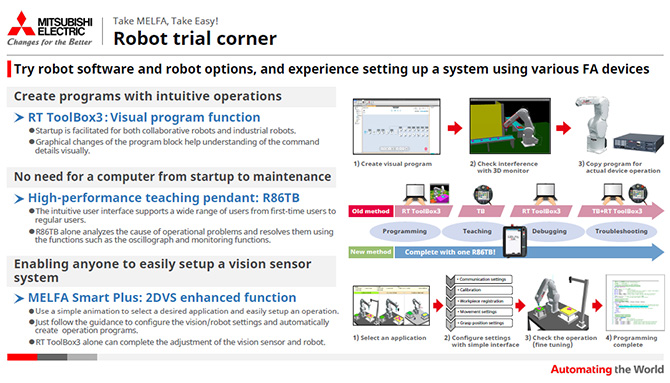

Take MELFA, Take Easy!

In addition to the FA product interaction function, you can also experience various dedicated models of more than 200 companies of the MELFA Robot Partner Association.

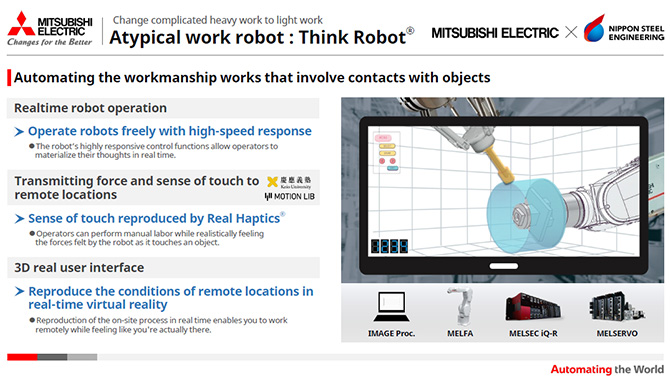

Atypical Work Robot

With flexible remote control technology and various user interfaces, we reproduce the ideas of skilled workers through our robots.

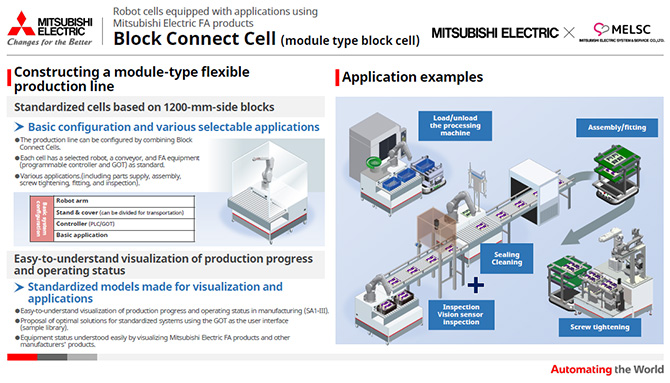

Quick delivery with applications as standard equipment

High scalable system by standarization of robot cells and linkage.

MELSERVO is used for the screw tightening unit, and a defect detection function is also added.

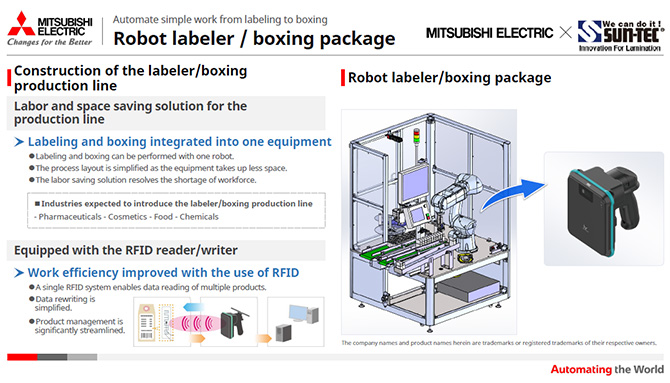

Automates simple tasks from labeling to box packing

Automation improves productivity, achieves labor saving, and stabilizes quality. Using RFID labels improves the work efficiency.

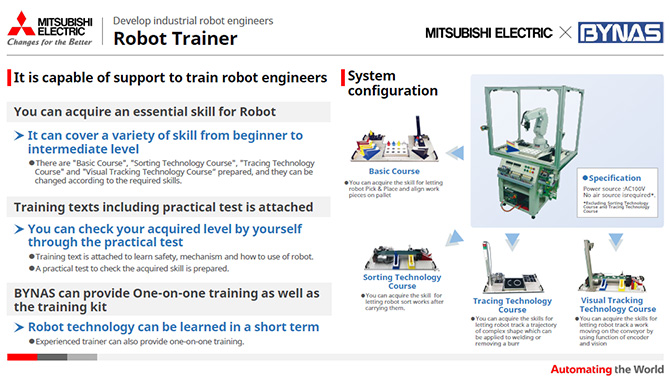

Training Industrial

Robot Engineers

Providing educational curriculum and one-on-one training, that enable to train professional robot engineers in a short term.

Robotic Laser Soldering for Automotive of EV shift

High-power laser soldering robot with high reliability, stablity and traceability for mass production.

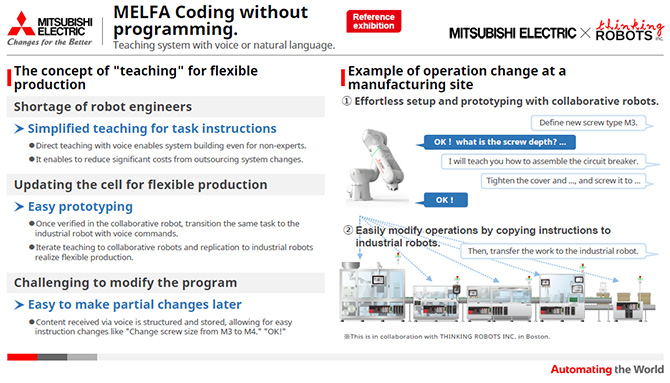

MELFA no-code programming

No-code programming further improves the work efficiency also for industrial robots.

We would like to introduce our future teaching method.

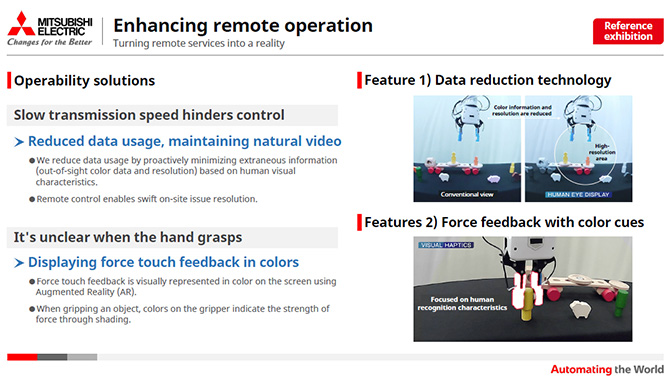

Making remote services a reality

We offer remote operation solutions to revolutionize future robot support.

Experience the new dimension of operation with high-speed communication and force sense transmission interface.

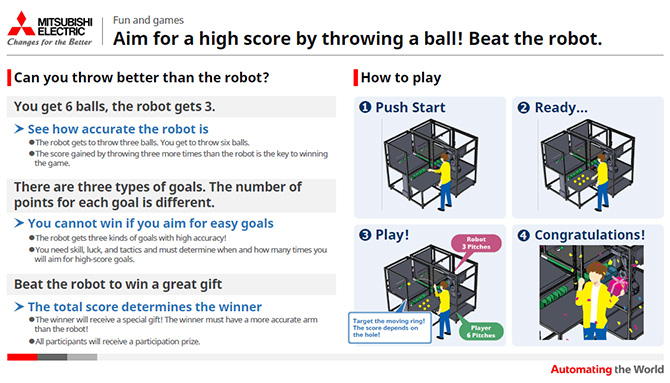

Aim for a high score by throwing a ball! Beat the robot.

The industrial robot who usually works in the factory takes on the ball-throwing task! Can you beat the robot?

If you beat the robot, you can get a prize!